Offshoring manufacturing to the right country is a great option if your business needs to reduce operating costs while maintaining quality standards.

It offers advantages like easier access to resources and specialized suppliers. But depending on the offshore location, it can come with various challenges as well.

So, which are the best countries for offshore manufacturing?

In this article, we’ll decode offshoring manufacturing and explore the four best countries for offshoring. We’ll also cover six key benefits and four drawbacks of offshore manufacturing so that you have all the details you need to finalize your offshoring decision.

Table of Contents

- What does offshoring manufacturing mean?

- 4 best countries for offshore manufacturing

- 6 main benefits of offshore manufacturing

- 4 important drawbacks of offshoring

Let’s get started.

What does offshoring manufacturing mean?

Offshoring manufacturing is when businesses relocate their manufacturing or production operations to another country. It allows businesses to capitalize on benefits like reduced costs and skilled workers. And unlike outsourcing, it enables greater control over each manufacturing activity.

How does offshoring differ from outsourcing?

Outsourcing is when a business hires a local or offshore third-party vendor to control specific aspects of its operations on a contractual basis. It allows the business to delegate functions to the vendor, like product assembly, resource procurement, or goods production.

Conversely, offshoring brings businesses into emerging countries, where they usually develop a home-grown offshore team to run their operations. This offshore team is still a part of the parent business.

For example, Ford Motor Company is an American vehicle manufacturer that owns and runs an offshore production setup in China.

On the other hand, Nike doesn’t own any of the factories it employs in offshore countries. Instead, it utilizes offshore outsourcing and has contractors to manage its production operations. Similarly, Ford employs business process outsourcing contractors in India to handle its IT and customer services.

Explore a detailed comparison between offshoring and outsourcing in this article.

The idea is to offshore the manufacturing operation to a developing country with lower labor costs, more lenient regulations, and favorable tax conditions.

For example, a US company may choose to offshore its manufacturing process to Mexico due to the region’s lower wages. Mexico’s minimum wage is a fraction of the minimum wage for U.S. workers.

The federal minimum wage in the United States is about USD 58 per day (according to the United States Department of Labor). On the other hand, Mexico’s minimum wage is MXN 141.7 (approximately USD 7.1 as of March 2022) per day.

Now that you’ve understood offshoring, let’s look at the best countries for offshore production.

4 best countries for offshore manufacturing

Here are the four best countries for offshore manufacturing operations:

1. Mexico

The USMCA (United States-Mexico-Canada Agreement) and the IMMEX Program (Spanish acronym for Manufacturing, Maquila, and Export Service Industry) make it easy for companies to offshore operations to Mexico.

What are maquiladoras?

Maquiladoras are foreign-owned low-cost manufacturing facilities in Mexico. They’re one of the main reasons companies choose to offshore to Mexico.

Here are some other key benefits of offshoring to Mexico:

- Low labor cost.

- A skilled talent pool with a large population of engineers.

- Strong protection of intellectual property rights.

- Ready-to-use infrastructure.

- Beneficial international trade agreements.

Note: USMCA is the updated agreement that replaced NAFTA (North American Free Trade Agreement). Both agreements served to bring structural changes to trade restrictions in North America, making Mexico a favorite destination for US manufacturers.

Industrial giants like Honeywell and General Motors have offshored to Mexico.

Go through this guide to know more about nearshoring to Mexico.

2. China

China is a leading destination for outsourcing, but it offers plenty of benefits for offshoring manufacturing units as well.

Here’s why multinationals consider offshoring to China:

- Low wage rates.

- Skilled workforce with collaboration and problem-solving skills.

- Cheap real estate for manufacturing facilities.

- Largest manufacturing sector in the world.

- Resource-intensive manufacturing – involving the efficient use of resources like energy and raw materials.

Many top companies, like Nike and Apple, run offshore manufacturing operations in China.

Find out more about outsourcing to China in this article.

3. India

India’s government initiatives aim to increase manufacturing employment by creating 100 million jobs in 2022. In 2021, India had 27.3 million filled manufacturing jobs – more than double the 12.284 million filled manufacturing jobs in domestic American companies.

Moreover, India has become one of the leading offshoring destinations for manufacturing.

Here’s why:

- Attractive cost advantages.

- Young labor force with a large pool of engineers.

- English language proficiency.

- Established electronic, automobile, and pharmaceutical manufacturing industries.

- ISO (International Organization for Standardization) compliance.

- Tax-related benefits.

Global companies like Microsoft and General Electronics offshore to India.

Discover more on why India’s an attractive offshoring destination in this article.

4. The Philippines

The Philippines has a top-notch supply chain for electronic manufacturing – which helps it maintain an efficient production cycle.

But there are many more benefits that companies can avail, including:

- Lower wages that rank among the lowest in the world.

- Excellent manufacturing industry, covering a broad range of services like electronic and food manufacturing.

- Good work culture with a strong emphasis on productivity.

- Tax benefits that favor foreign companies, including a four-year corporate income tax exemption and duty-free imports for supplies and raw materials.

- Low-risk potential due to economic stability and beneficial economic policies.

There has been a large surge in companies offshoring to the Philippines, like Avon and Johnson & Johnson.

Discover everything about offshoring to the Philippines in this article.

And if you want more options, explore the best countries for offshoring in this guide.

Now that you have a good idea of the best countries, let’s look at the benefits of setting up an offshore manufacturing operation.

6 main benefits of offshore manufacturing

Here are the major offshoring benefits for businesses:

1. Cost savings

The main motivation and the biggest incentive for businesses in offshore manufacturing is the low labor cost. It’s an effective means for companies to save costs and increase their throughput (the amount of materials passing through a process).

Moreover, firms can save costs on other aspects, including:

- Cheaper rates for real estate.

- Lower costs of raw materials.

- Reduced expenses on intermediate inputs, like energy and services.

- Lower transport or freight cost.

Ultimately, increased cost savings lead to higher profit margins.

2. Skilled workforce

The availability of a skilled workforce, especially in manufacturing operations, is another major reason businesses choose offshoring.

For manufacturing, a business may look for emerging countries with a vast labor market and a low median age. But it’s especially helpful when the workforce has the right skill-set and training to maintain the quality of the product.

Offshoring can help shape employment and the demand for skills in a developing country.

Moreover, offshore production helps businesses overcome manufacturing employment issues.

These issues are widespread in developed countries, like France, Germany in Western Europe, and the US in North America. It is evidenced by growing talent shortages and increasing disinterest in manufacturing as a long-term career.

How does offshore manufacturing help?

Employment in offshore locations provides companies with a larger worker pool than those available in developed countries.

3. Proximity to the raw material source

Securing and transporting raw materials from other countries has always been an added expense for manufacturing firms.

But production offshoring can help them increase their proximity to the raw material source and reduce transport and purchase costs. Moreover, there is less damage to the raw materials since it doesn’t have to undergo long-distance transportation.

4. Specialized suppliers

Offshore production also helps businesses find specialized suppliers that don’t usually exist in their domestic markets.

This, in turn, lets businesses access higher-quality resources at lower prices. An ideal supplier will also have the right equipment, experience, and systems, helping you improve the quality of your final products.

These suppliers help businesses acquire a competitive edge through a unique access to relevant technology and production strategies.

5. Transfer of risk

When businesses partner with reliable suppliers and workers for offshore activities, they reduce some of the capital risks associated with scaling up operations.

It gives businesses a safer opportunity to increase their operations by spending less on labor, high-tech equipment, and overhead costs. And transfers some of the risks to parties who would handle the operations for them.

6. Access to new markets

In addition to greater cost savings, offshore manufacturing allows businesses to enter international markets and develop new customer bases. In short, it furthers globalization.

It helps businesses tap into the global supply chain and gain new insights into efficient manufacturing techniques via an offshore subsidiary.

Moreover, production offshoring leads to the creation of new manufacturing economies in countries that have easier access to the necessary resources. It creates a stable environment for businesses to grow.

Check out this article to know more about the amazing benefits of offshoring.

But do these offshoring benefits come with any challenges?

4 important drawbacks of offshoring

Although offshoring has international economic benefits for businesses, it may have a few drawbacks as well, such as:

1. Unmet quality and productivity standards

The work standards of manufacturing workers in a foreign country may not always meet the quality standards of the parent company.

Why?

Offshore manufacturing conditions and regulations can differ from those in a company’s home country. Moreover, issues like breaks in the local supply chain and reduced service quality can negatively affect brand value.

How can businesses overcome these quality control issues?

Offshore businesses can:

- Create a management team that understands local regulations and administration.

- Set up a production process with regular checks for timely delivery and quality assurance.

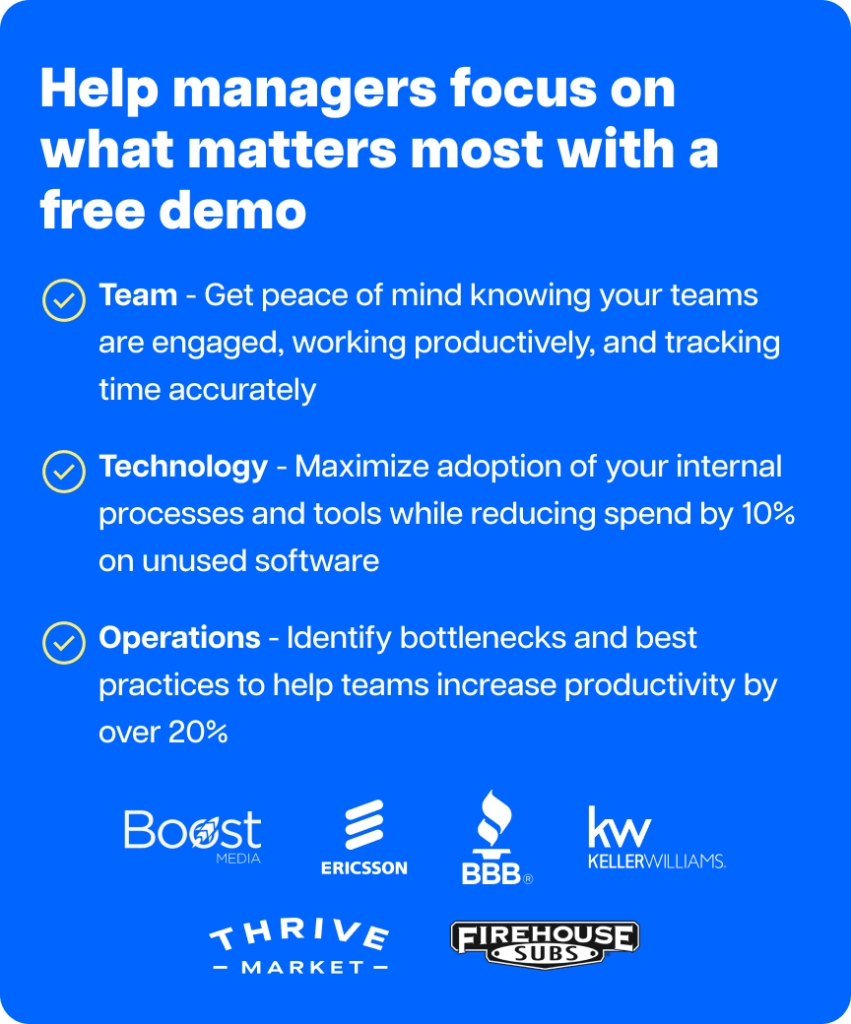

- Employ software tools for employee productivity and time tracking, like Time Doctor. Its time management features can help offshore employees maintain a fixed standard of work productivity acceptable to employers.

- Train their offshore teams to address delays or quality issues and create incentives for meeting quality and productivity goals.

2. Risks to data security and intellectual property

Patent protection and data privacy laws are country-specific. So, when businesses move their production process to offshore locations, they are more at risk of data breaches and loss of intellectual property.

Moreover, in some cases, offshoring may require businesses to provide key strategies of the production process to contractual employees. In such scenarios, there’s a higher risk of loss of intellectual property when the contract employees leave their roles.

So, companies should take steps to safeguard their business strategies and data. Failing to do so can lead to higher import competition with other companies importing the same goods and services.

What can businesses do to protect their data?

Hire lawyers and data security professionals who understand the offshore country’s data protection laws. Businesses can also apply for patents in offshore countries or have manufacturing workers sign NDAs or Non-Disclosure Agreements. NDAs will help protect your business’s advanced manufacturing strategies.

Discover the key components of a comprehensive outsourcing agreement.

3. Risk of non-compliance

Regulatory and corporate compliance are important aspects of operating in a foreign country. And depending on the location, multinational corporations may need to follow different compliance regulations.

For example, each country has different labor and environmental regulations. And businesses need to follow these regulations to ensure they don’t have to pay fines or penalties.

How do companies address compliance?

Multinational corporations usually hire experts that understand the local manufacturing regulations or outsource certain functions, like payroll or HR, to an experienced service provider.

For example, a third-party provider that handles HR and payroll will ensure that manufacturing companies follow local regulations for overtime or individual income tax laws. It’ll help companies cater to their contracted workers’ needs as well.

For added security, companies could also hire in-house legal experts to mediate legal disputes.

4. Communication and language issues

In some cases, the offshore location may have workers that only speak the native language. This can be a problem if managers aren’t able to communicate clear instructions that concern urgent deliverables.

Additionally, management in the parent company may not completely understand the offshore location’s culture. This could lead to misunderstandings about the expected work ethic.

How can you bridge the communication gap?

Businesses can hire managers or supervisors who are fluent in the local tongue. They can also create policies to celebrate local customs and learn more about the region’s culture.

Overcoming all of these challenges helps businesses achieve manufacturing success in offshore locations. On the other hand, an inability to resolve them is why firms look at reshoring as a solution.

What is reshoring?

Reshoring or onshoring is the reverse of offshoring. It involves the return of a manufacturing operation to the business’s parent country.

In recent years, reshoring has seen a surge due to the COVID pandemic.

Here are a few reasons why reshoring has increased:

- Automation and robotics have driven a reduction in the need for labor.

- Lucrative incentives offered by the parent country’s government to reduce job losses in their country.

- Import trade tariffs levied by the parent country or an overseas market on the transport of goods from offshore countries. This is done to reduce a trade deficit.

- Hefty transportation costs on the movement of goods between the offshore and the parent country.

- Supply chain issues due to the pandemic.

But reshoring can lead to additional production costs and increase the risks of scaling the business. Moreover, wage increments are a lighter burden in most offshoring destinations. So, reshoring isn’t always the best solution for businesses.

Refer to this guide for a detailed view of the disadvantages of offshoring and how to overcome them.

Wrapping up

Offshoring manufacturing allows businesses to thrive while maintaining profitable operations.

It helps businesses scale up while allowing them to offer products to customers at competitive prices.

So, use the information in this article to see if your business could thrive with the benefits of offshore manufacturing.

Andy is a technology & marketing leader who has delivered award-winning and world-first experiences.